Fillers - Can Filling Machines

Used Fillers - Can Filling Equipment

Filler Can Equipment – Can fillers are designed to fill cans with a certain volume of liquid, paste, or other type of product. Can filling machines can be designed with different types of mechanisms to determine the proper volume of product to be filled including, piston fillers, liquid fillers, and pocket fillers. They are similar in operation to liquid and powder filler with the largest difference being that can fillers are specifically designed to handle cans while liquid and powder fillers are designed to handle glass, plastic, and other types of containers.Piston can fillers use a piston to measure out the proper volume of product to insert into the can. As the piston is drawn up, the piston draws in product from the product holding to fill the piston. Once the piston is full, a rotary drum valve, which controls the direction of inflow and discharge of product from the piston, is rotated so that as the piston compresses it will push the product out of the piston and into a can. Once the piston has emptied, the drum valve is rotated back so that as the piston is drawn up, the piston will draw product from the product hold tank. Piston can fillers can be used for liquids and pastes.Liquid can fillers are similar to liquid gravity fillers in that gravity can fillers utilize the pressure of gravity on a liquid product to fill the product into the can. Gravity can fillers plunge a nozzle into the can that has a gasket that forms a seal with the top of the can.

The nozzle on the liquid can filler then opens to allow product to flow from the product hold tank. Once the liquid reaches a level above the filling ports in the nozzle, the head pressure above the liquid in the can is equal to the pressure above the liquid in the product hold tank. Once this occurs, the liquid stops flowing into the can. As the nozzle is raised out of the can, the nozzle closes to prevent more product from entering the can.

Related Categories

Fillers - Can Filling Equipment In Stock

Solbern Filler Can Liquid LCB

- Manufacturer: Solbern

- Model Number: LCB

- Frain Number: 5H1063

Solbern Model LCB stainless steel, in-line free standing, self driven economic briner designed for running one or various size containers on the same line with containers per minute – depending on materials and application. Equipped 58" long x 10" wide x 10" high stainless steel top product tank and with 156" long single 1/4" OD rubber container belt, with guide rails, containers are angled to regulate head space for accurate fills and slight over flow. thru and before leaving the fill area and has 80" long x 24" wide x 16" high bottom stainless steel overflow tank with perforated particle panels. All stainless steel sanitary piping and Waukehaw 130 PD pump.

OAD: 156" L x 66" W x 79" H

Get a Free Quote Call: 630-629-9900MRM Elgin Filler Can Piston RPF-16

- Manufacturer: MRM Elgin

- Model Number: RPF-16

- Frain Number: 5E0184

MRM Model RPF-16, Automatic, 16 head, rotary, piston filler rated up to 240 containers per minute – depending on materials and application. Containers up to 5" in diameter x up to 12" height. Maximun fill volume of 35oz both with proper change parts. Currently equipped with 2.5 oz pistons. wormscrew to starwheel in feed and discharge, 6" wide x 5-1/2" deep platforms, 1/4" OD fill nozzles, with bottom-up fill, 50 gallon product tank with float valve and has 3" diameter tri-clover product inlet, hand crank volume adjustment for all pistons, volume adjustments for individual pistons, neck centering guides, and no container / no fill, start and e-stop. Mounted on heavy duty frame with height adjustable feet and stainless steel guarding.

OAD: 60"L x 84"W x 84"H

Get a Free Quote Call: 630-629-9900MRM Elgin Filler Can Piston RPF-16 16 Head Rotary

- Manufacturer: MRM Elgin

- Model Number: RPF-16

- Frain Number: 5E0149

MRM Elgin Model RPF-16, Automatic, 16-head rotary, piston filler rated from 50 to 240 fills per minute – depending on materials and application. Containers: up to 4-3/4" in diameter x up to 12" in Height. Equipprd with 3-1/2" Wide conveyor frame, worm screw to star wheel in feed and discharge, neck centering guides, 3/8" diameter nozzles, Maximum fill of 52oz with fill accuracy +/- 0.5% by volume (with proper change parts), mechanical container height adjustment, no container / no fill. Control panel has a Micrologic controller with (3) Powerflex vari-speed controllers and power, conveyor and filler speed control dials, start, stop and e-stop push buttons. Mounted on base frame with electrical interlock, barrier safety guarding.

OAD: 92"L x 68"W x 90"H

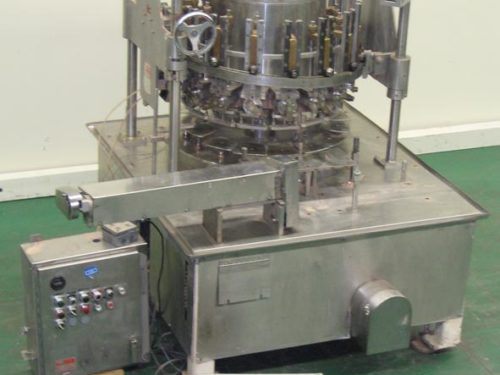

Get a Free Quote Call: 630-629-9900Hema Filler Can Piston MR30 Hema S/S 30 head rotary piston filler

- Manufacturer: Hema

- Model Number: MR30

- Frain Number: 5D6071

Hema Model MR30, Automatic, continuous motion, stainless steel, 30 head rotary filler, rated from 50 to 500 container per minute – depending on materials and application. Equipped with timing screw to starwheel wheel infeed and discharge currently has 9.5 oz pistons set on 5-3/4" centers with drum valves (for heavy particulates) and is handcrank adjustment, has 1/2" ID nozzles and top product chamber with no container / no fill. Mounted on stainless steel frame with product drip catch platform. Last running 2-1/2" OD. x 3" High containers.

OAD: 80" L x 122" W x 75" H

Get a Free Quote Call: 630-629-9900Elmar / Votator Industries Filler Can Piston PB9G

- Manufacturer: Elmar / Votator Industries

- Model Number: PB9G

- Frain Number: 5D1261

9 head rotary, S/S piston filler capable of speeds depending on application. All S/S contact parts has 9 filling heads set on 8-1/2" centers, (9) 7" Dia x 7" L pistons, fills to 128 ozs, with accuracies of 0.1 fluid oz and containers to 603 Dia x 12" H, with proper change parts. Has 5" L x 8" W bottom up fill container pedestals and container grippers no container / no fill, S/S drip pan, 72" L x 4 1/2" W plastic delrin container conveyor with 36" L worm screw in feed and container guide rails, control panel with run / jog switch and e-stop.

OAD: 112" L x 72" W x 96" H

Get a Free Quote Call: 630-629-9900MRM Elgin Filler Can Piston RPF8

- Manufacturer: MRM Elgin

- Model Number: RPF8

- Frain Number: 5H9181

MRM Model RPF8, Automatic 8 head rotary piston filler capable of speeds from 20 to 120 container per minute – depending on product and fill volume. Maximum container size: 5" diameter x 12" height. Equipped with 14 gallon, heated hopper and has level detector, mechanical container height and piston adjustment, no container / no fill, 4-1/2" x 6′ conveyor track, stainless steel contact parts and Lexan guarding.

Air requirements: 60 psi at 1 CFM.

Maximum fill volume per application (with proper pistons)

Left to right product flow.

OAD: 120" L x 48" W x 80" H

Get a Free Quote Call: 630-629-9900Elmar / Votator Industries Filler Can Piston RPE-514I LH

- Manufacturer: Elmar / Votator Industries

- Model Number: RPE-514I LH

- Frain Number: R35810

Elmar, Model RPE-514I LH, Automatic, 14 head rotary piston filler rated from 50 to 300 containers per minute – depending on materials and application Stainless steel contact parts. Equipped with 4½" wide x 64" long infeed conveyor, worm screw to star wheel indexing, 14 filling heads set on 6¼" centers, 2¾" diameter x 6" long pistons, and ½" OD filling nozzles maximum fills of 20 fluid onces. Container size range 2" to 4¼" OD and 19" diameter x 25" deep filler bowl with maximum capacity of 25 gallons and 4½" wide discharge conveyor. Can handle plastic, glass, composite and tin containers with proper change parts. Control panel with touch screen HMI and safety guading cage.

OAD: 152"L x 116"W x 85"H

Get a Free Quote Call: 630-629-9900Elmar / Votator Industries Filler Can Piston RPE-514G I RH

- Manufacturer: Elmar / Votator Industries

- Model Number: RPE-514G I RH

- Frain Number: 5H8080

Elmar, Model RPE-514G Automatic, 14 head rotary piston filler with number of containers per minute and hour – depending on materials and application. Equipped with 6" wide in feed conveyor, worm screw to star wheel indexing, 14 filling heads set on 10¼" centers, (14) 6½" OD x 10" long pistons, fills from 32 onces to 170 onces. Mounted on (4) leg base frame with safety cage guarding.

OAD: 96"L x 80"W x 98"H

Get a Free Quote Call: 630-629-9900FMC Food Tech Filler Can Piston C100

- Manufacturer: FMC Food Tech

- Model Number: C100

- Frain Number: 5B1011

Fully automatic 10 head rotary piston filler capable of speeds from 50 to 250 cpm (depending on can size & fill). Has container size range: 202 – 404 dia x 101 – 700 Height, with proper change parts. Equipped w/10 gal (38 liter) 15 1/8" dia hopper, 41" L x 3 1/4" W conveyor, worm screw/starwheel infeed & spaces container 6.25" apart. Has 3" piston with min/max stroke of 1/2" – 5 1/4" for 21 oz max capacity .

Get a Free Quote Call: 630-629-9900Solbern Filler Can Liquid LCB

- Manufacturer: Solbern

- Model Number: LCB

- Frain Number: 5H1058

Solbern Model LCB stainless steel, in-line free standing self driven economic briner designed for running one or various size containers on the same line with containers per minute – depending on materials and application. Equipped 58" long x 10" wide x 10" high stainless steel top product tank and with 168" long single 1/4" OD rubber container belt, with guide rails, containers are angled to regulate head space for accurate fills and slight over flow. thru and before leaving the fill area and has 83" long x 24" wide x 16" high bottom stainless steel overflow tank with perforated particle panels. All stainless steel sanitary piping and Waukehaw 130 PD pump.

Mounted on height stainless steel frame with adjustable leveling legs.

OAD: 168" L x 56" W x 83" H

Get a Free Quote Call: 630-629-9900Solbern Filler Can Liquid LSB

- Manufacturer: Solbern

- Model Number: LSB

- Frain Number: 5H1059

Solbern Model LSB stainless steel, in-line seamer-driven briner designed for high speed brining and saucing or the addition of any free-flowing liquid such as broth, to pre-filled container without spillage with number of containers per minute – depending on materials and application. Equipped 58" long x 10" wide x 10" high stainless steel top product tank with 60" long feed screw thru fill zone, containers are angled to regulate head space for accurate fills and slight over flow before leaving. Has 78" long x 19" wide x 16" high bottom stainless steel overflow tank with perforated particle panels. Prior to exiting the feed screw containers are spaced to the precise seamer pitch and are picked up by the seamer chain, providing a smooth transfer without spillage. All stainless steel sanitary piping and Waukehaw 130 PD pump. Mounted on height stainless steel frame with adjustable leveling legs.

OAD: 126" L x 43" W x 80" H

Get a Free Quote Call: 630-629-9900FMC Food Tech Filler Can Solid 30PKT

- Manufacturer: FMC Food Tech

- Model Number: 30PKT

- Frain Number: 5G2614

30 pocket continuous motion volumetric can filler, 5" center. Rated from 50 to 350 containers per minute – depending on materials, application and machine configuration. Can size : 1"-4" Diameter and 1" to 8". Fill range 1" to 3.5"diameter X 1" to 8"depth. Equipped with open top, 55" diameter plate, product scrapers, SLC500 PLC, run/jog switch, e-stop and start buttons. Change parts required to accommodate size range.

OAD: 92" L x 80" W x 92" H

Get a Free Quote Call: 630-629-9900