Tunnel Machines

Used Tunnel Equipment

A freeze tunnel is a process where the materials to be frozen are placed on an endless conveyor and passed through the tunnel where the refrigerants are used to cool the air and through circulation allow the material to become frozen. Other variations of the freeze tunnel process are the direct immersion tunnel systems where the refrigeration media is sprayed onto the product. This is a cryogenic freeze tunnel. A final variation of the freeze tunnel process is a quiescently frozen process for freezing materials in molds such as frozen ices in cups or forms and frozen in that shape and removed upon freezing for final wrapping. The refrigerants can be either chiller brines or cryogenic gases for achieving the required degree of freezing.

Related Categories

Tunnel Equipment In Stock

BOC Gasses / Linde Freezer Tunnel KFT-36-10M

- Manufacturer: BOC Gasses / Linde

- Model Number: KFT-36-10M

- Frain Number: 5J6080

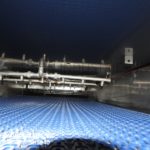

BOC gases, model KFT-36-10M, 304 stainless steel, Co2 freeze tunnel. Rates dependant on materials, application and machine configuration. Equipped with 38" wide x 152" long stainless steel mesh product conveyor with a 40" infeed and discharge height, 5½" high x 35½" wide aperture, 121" long freeze chamber, 3 banks of spray nozzles with 3 nozzles each, (2) top mounted circulation fans each powered by a 1 hp drive.

OAD: 175" L x 53" W x 93" H

Get a Free Quote Call: 630-629-9900CES / DSI Dantech Freezer Tunnel CES-LT-LIN-50FTX38IN

- Manufacturer: CES

- Model Number: CES-LT-LIN-50FTX38IN

- Frain Number: 5J3996

CES, model CES-LT-LIN-50FTx38IN-HOTL liquid nitrogen freeze tunnel with amount of product per hour – depending on materials and application. Equipped with 38" wide x 713" long stainless steel mesh belt with 38" to 42" infeed and discharge height powered by 1½ Hp motor drive, 640" long cooling chamber with 10" high aperture, (2) 15"OD / 12"ID flanged exhaust connections, (18) 1 HP motor circulation fans and lifting hood. Control panel has A/B controller with touch screen HMI. Mounted on multi-leg frame.

OAD: 723"L x 88"W x 76"H

Get a Free Quote Call: 630-629-9900CES / DSI Dantech Freezer Tunnel CES-LT

- Manufacturer: CES

- Model Number: CES-LT

- Frain Number: 5J2656

Cryogenics Systems, Model CES-LT-LIN-20FTx2FT-PODB, liquid nitrogen freeze tunnel. Equipped with a 25" wide x 282" long belt with a 33" infeed / discharge height, 240" long freeze chamber with a 29" wide x 8½" high aperture, (5) fans powered by 1 HP drives and drop down guarding. Control cabinet has AB PLC and touch screen HMI.

OAD: 300"L x 70"W x 88"H

Get a Free Quote Call: 630-629-9900West Coast Cryogenic Services Freezer Tunnel TUNNEL FREEZER

- Manufacturer: West Coast Cryogenic Services

- Model Number: TUNNEL FREEZER

- Frain Number: R38590

West Coast Cryogenic, 20′ long, freeze tunnel with amount of product per hour – depending on materials, application and machine configuration. Equipped with 42" wide x 312" long flat top belt with 38" to 42" infeed and discharge height powered by ½ Hp motor drive, 240" long cooling chamber with 42" wide x 8½" high aperture, (2) 16"OD / 11"ID flanged end exhaust hood connections, (4) CIP spray balls supplied by 2½"OD / 2"ID Tri-Clamp fittings and (4) 1½ HP motor circulation fans. Control panel has A/B controller with touch screen HMI. Mounted on multi-leg frame. Currently configured as CO2. Can be configured for nitrogen.

OAD: 322"L x 68"W x 90"H

Get a Free Quote Call: 630-629-9900Liquid Carbonics Freezer Tunnel JE-U4

- Manufacturer: Liquid Carbonics

- Model Number: JE-U4

- Frain Number: 5J0060

Liquid Carbonics, Model JE-U4 inline, stainless steel freeze tunnel. Equipped with 40" wide by 292" long stainless steel mesh product conveyor (33" in feed and discharge height), 256" long chamber with flip up access doors each side, 40" wide by 9" high product aperture. five banks of spray nozzles and top mounted circulation fans. Rated dependent on materials, application and machine configuration. Controls to be upgraded to AB PLC with touch screen. Currently configured for CO2. Can be converted to Nitrogen.

OAD: 300"L x 60"W x 101"H

Get a Free Quote Call: 630-629-9900DSI Dantech Freezer Tunnel CES 3 PASS

- Manufacturer: DSI Dantech

- Model Number: CES 3 PASS

- Frain Number: 5H8875

DSI Dantech Model CES-MP-LIN-30ft x 4ft-HOTL-PLC, 3-pass liquid nitrogen freeze tunnel with amount of product per hour – depending on materials, application and machine configuration. Stainless steel construction. Equipped with 48" wide stainless steel wire rod product conveyor belt, 55" high infeed, 32" high discharge, with 7" clearance between belt levels. (10) top mounted circulation fans and drives with top belt 33 feet long, middle belt 32 feet long and bottom belt 34 feet long. Remote control panel has A/B PLC with touch screen HMI. and A/B 525 Powerflex with statis light and e-stops. Mounted on heavy duty frame.

OAD: 475" L x 86" W x 90" H

Get a Free Quote Call: 630-629-9900DSI Dantech Freezer Tunnel CES 3 PASS

- Manufacturer: DSI Dantech

- Model Number: CES 3 PASS

- Frain Number: 5H8870

DSI Dantech Model CES-MP-LIN-30ft x 4ft-HOTL-PLC, 3-pass liquid nitrogen freeze tunnel with amount of product per hour – depending on materials, application and machine configuration. Stainless steel construction. Equipped with 48" wide stainless steel wire rod product conveyor belt, 55" high infeed, 32" high discharge, with 7" clearance between belt levels. (10) top mounted circulation fans and drives with top belt 33 feet long, middle belt 32 feet long and bottom belt 34 feet long. Remote control panel has A/B PLC with touch screen HMI. and A/B 525 Powerflex with statis light and e-stops. Mounted on heavy duty frame.

OAD: 475" L x 86" W x 90" H

Get a Free Quote Call: 630-629-9900Frigoscandia Freezer Tunnel AGA

- Manufacturer: Frigoscandia

- Model Number: AGA

- Frain Number: 5H8410

Frigoscandia Model AGA, in line, stainless steel, cryogenic, nitrogen gas, belt style freeze tunnel with temperatures and number of product per hour – depending on materials, application and machine configuration. Equipped with 47" wide x 8" high aperature x 250" long stainless steel nitrogen freeze chamber with access covers and 47" wide x 286" long stainless steel mesh conveyor belt with 40" in feed and discharge heights, has nitrogen freeze zone and nozzles, with (7) top mounted turbulation circulation fans, spray header, gas exhaustion manifold and temperature probes. Control panel has temperature and freeze time, evacuation and belt speed controllers with e-stops. Mounted on stainless steel (4) leg frame.

Model AGA, is a continuous in-line belt freezer designed for gentle product and minimum loss of product weight during freezing.

OAD: 324"L x 68" W x 70" H

Get a Free Quote Call: 630-629-9900Air Products Freezer Tunnel FRESHLINE QS

- Manufacturer: Air Products

- Model Number: FRESHLINE QS

- Frain Number: 5H5940

Air Products, Model Freshline Quick Start, Stainless steel, liquid nitrogen freeze tunnel. Equipped with 278" long (3 section) tunnel chamber, 40" wide x 4" high aperture with adjustable height shield, flip-up access doors, side hand cranks for lowering the bottom section of tunnel and 8" OD exhaust duct. Link belt conveyor 38" wide x 315" long. Quick Freeze system with liquid nitrogen spray nozzles for direct contact with product. Controller with operator interface, digital readout for freezer and exhaust temperature, product retention time and conveyor speed controls. E-stops on each end of the tunnel. Mounted on height adjustable legs. Rates dependent on materials, application, and machine configuration.

OAD: 331" L x 66" W x 63" H

Get a Free Quote Call: 630-629-9900Cryogenics System Equipment / Freezer Tunnel CRYOGENIC

- Manufacturer: Cryogenics System Equipment /

- Model Number: CRYOGENIC

- Frain Number: 5H3717

Praxair / Liquid Carbonics / Cryogenic Systems Equipment, compack, stainless steel, cryogenic, LN2 (liquid nitrogen) freeze tunnel with amount of product per hour – depending on materials and application. Equipped with 107" long freeze tunnel and has 36" wide x 3-1/2" high total aperture with dual 107" long flip up side access doors one each side with (2) sets of (7) liquid nitrogen inner chamber spray nozzles and (2) inner chamber circulation fans with a 107" long x 34" wide stainless steel solid flat band product conveyor belt with 36" high in feed and discharge chutes and top mounted LN2 (liquid nitrogen) injection panel. Control panel has ABB controllers with spray system and fan on / off switches, pressure gauge with 0 to 210 psi and 0 to 30 Hg vacuum ratings. Mounted on a heavy duty stainless steel base frame.

OAD: 200" L x 80" W x 94" H

Get a Free Quote Call: 630-629-9900