Training Videos

Magnetic Mounting

Magnets can be a useful means of eliminating tools during changeover. In some cases, the magnet can provide 100% of the holding force. A common holder for surface grinding uses only a magnet to hold the workpiece.

These may have some applications in packaging, though I’ve not run across any yet. A more common application is to mount the changepart mechanically using slots and keyholes. Once in place, the configuration prevents it coming loose.

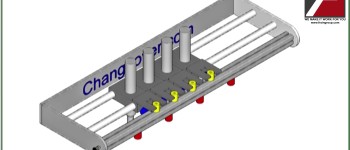

The problem is that, absent some sort of fastener, the changepart can vibrate out of position. Here is where magnets come into play. The video, and the picture below, show a pusher mounted to a conveyor chain. The pusher base drops into the matching hole on the lug. When the pusher is slid back about 1/4″, tabs engage locking it in place vertically. The normal pushing load holds the pusher in place.

When not under load, the pusher could vibrate forward and up causing a jam or damage. twelve small but powerful magnets prevent this. When the pusher is in its correct position, the magnets align and prevent it from moving forward accidentally.

This tool-less mounting allows operators to change the pushers rather than requiring a mechanic as in some companies. More importantly, if there are 20 pushers and it takes 1 additional minute to replace each by unbolting and rebolting, this eliminates 20 minutes of downtime.

If the cost of downtime is $10,000/hour, this represents a saving of over $3,000 per changeover.

Hard to believe that a tiny magnet can save that much money.

But it can.